To identify early signs of wear and tear in construction machinery, pay attention to unusual noises and vibrations, like grinding or excessive rattling. Notice any decreases in performance, such as slower operation or longer cycle times. Regularly inspect key components, focusing on hydraulic systems for leaks and undercarriage parts for tire wear. Implement preventive maintenance, including routine lubrication and fluid checks. If you want to discover more about effective maintenance strategies, keep exploring!

Key Takeaways

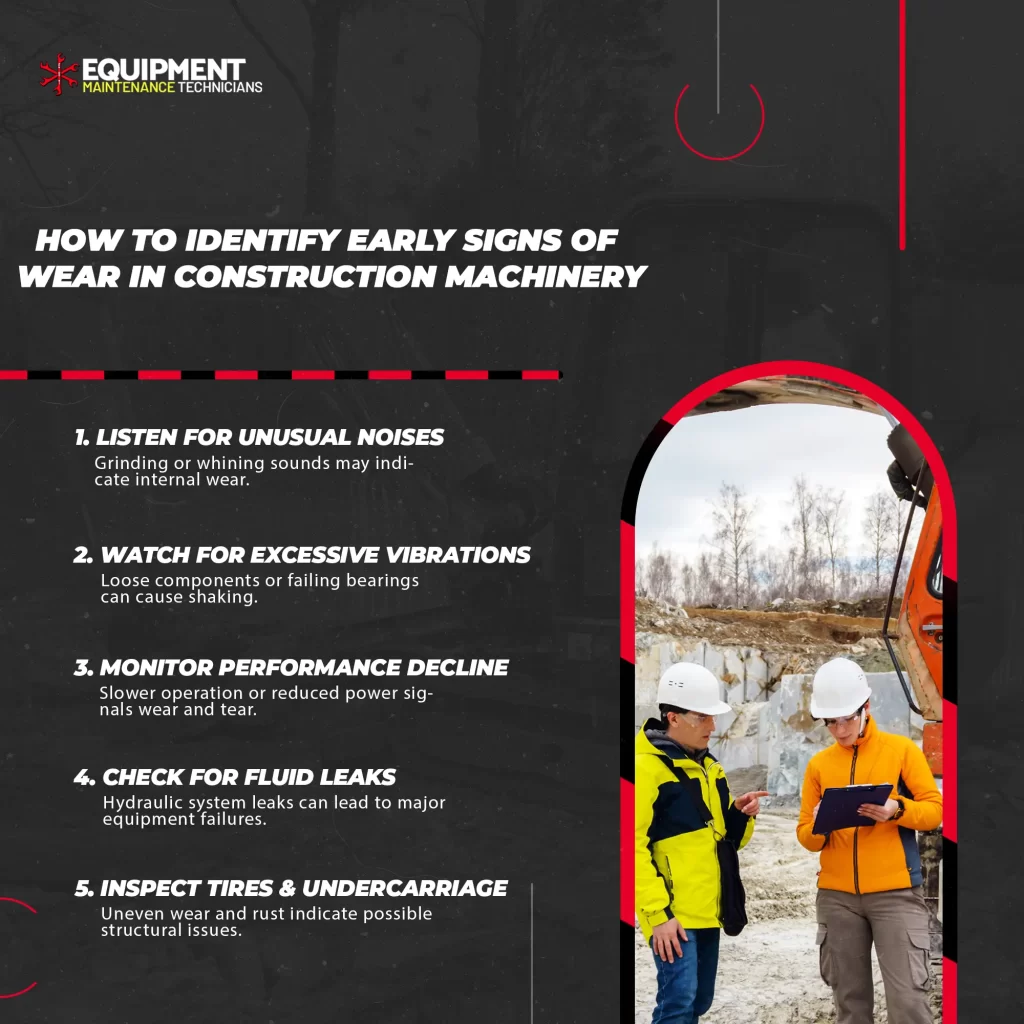

- Listen for unusual noises, such as grinding or whining, which may indicate internal damage or lubrication issues.

- Observe for excessive vibrations that could signal loose components or failing bearings in the machinery.

- Monitor performance metrics; slow operation or reduced power output can indicate underlying wear and tear.

- Regularly inspect hydraulic systems for fluid leaks and check hoses and fittings for signs of wear.

- Maintain a routine inspection schedule and document findings to track the condition of the machinery over time.

Common Signs of Wear and Tear in Construction Machinery

When you’re operating construction machinery, it’s essential to pay attention to unusual noises and vibrations, as these can indicate underlying issues. You might also notice a decrease in performance and efficiency, which often signals wear and tear. Recognizing these signs early can help you prevent costly repairs and keep your equipment running smoothly.

Unusual Noises and Vibrations

As you operate construction machinery, you might notice unusual noises and vibrations that signal potential wear and tear. Ignoring these signs can lead to more significant issues down the line. Here are three common types of unusual noises and vibrations to watch for:

- Grinding or Clunking Sounds: These often indicate internal damage or misalignment in gears.

- Excessive Vibrations: If you feel strong vibrations, it could mean loose components or failing bearings.

- High-Pitched Whining: This may suggest a problem with the hydraulic system or low lubrication levels.

Paying attention to these unusual noises and vibrations can help you catch equipment wear and tear early, preventing costly repairs, and ensuring your machinery runs smoothly.

Decreased Performance and Efficiency

Decreased performance and efficiency in construction machinery can often signal underlying wear and tear that needs immediate attention. If you notice your equipment struggling to complete tasks it once handled easily, it’s time to investigate. Slow operation, reduced power output, or longer cycle times are red flags indicating potential issues. These signs often stem from the wear and tear of equipment components, such as engines, hydraulic systems, or transmissions. Ignoring these symptoms can lead to more significant problems and costly repairs down the line. Regularly monitoring your machinery’s performance guarantees you catch these issues early, allowing for timely maintenance and repairs. Keeping your equipment in peak condition not only enhances efficiency but also prolongs its lifespan.

Inspecting Key Components for Early Damage Detection

When you’re inspecting construction machinery, focus on key components like hydraulic systems and the undercarriage. Look for fluid leaks and signs of tire wear, as these can indicate underlying issues. Catching these early can save you time and money in repairs down the line.

Hydraulic Systems and Fluid Leaks

Hydraulic systems are essential to the functionality of construction machinery, and even minor fluid leaks can signal early signs of wear and tear. Addressing these issues promptly can prevent costly repairs and downtime. Here’s what to check for in hydraulic systems:

- Fluid Levels: Regularly inspect fluid levels; a drop can indicate leaks.

- Hoses and Fittings: Look for cracks or loose connections that could lead to leaks.

- Fluid Quality: Check for discoloration or debris, which can indicate contamination.

Identifying these heavy equipment warning signs early can help you manage wear and tear in construction effectively. Stay proactive by monitoring your hydraulic systems to guarantee your machinery operates smoothly and efficiently.

Undercarriage and Tire Wear

While you focus on the overall performance of your construction machinery, don’t overlook the importance of inspecting the undercarriage and tires for early signs of wear. Heavy wear and tear in these areas can lead to costly repairs and downtime. Start by checking for cracks, tears, or uneven wear patterns on tires, as these can indicate alignment issues. For the undercarriage, look for signs of rust, excessive dirt accumulation, or damaged components. Regularly inspecting these parts helps you catch potential problems before they escalate. If you notice any abnormalities, it’s wise to consult an expert to address the signs of wear and tear promptly. Keeping your machinery in top shape guarantees safety and efficiency on the job site.

Preventive Maintenance Strategies to Reduce Equipment Downtime

To keep your construction machinery running smoothly, regular lubrication and fluid checks are essential. Implementing a routine inspection schedule can help catch potential issues before they escalate. By prioritizing these preventive maintenance strategies, you’ll considerably reduce equipment downtime and extend the life of your machinery.

Regular Lubrication and Fluid Checks

Regular lubrication and fluid checks are essential for keeping your construction machinery running smoothly. Neglecting these tasks can lead to increased equipment wear and tear meaning costly repairs and downtime. Here’s what you should focus on:

- Oil Levels: Regularly check engine oil levels and replace it as needed to guarantee proper lubrication.

- Hydraulic Fluids: Monitor hydraulic fluid levels and quality to maintain peak performance and prevent leaks.

- Grease Points: Identify and lubricate all grease points on your machinery to reduce friction and prevent wear.

Implementing a Routine Inspection Schedule

Establishing a routine inspection schedule is essential for guaranteeing your construction machinery remains in ideal condition. By setting regular intervals for checks, you can spot worn signs early and address potential issues before they escalate. Use temporary signs in construction and maintenance work areas to remind your team about upcoming inspections. This visibility can help reinforce the importance of maintenance and guarantee everyone is on the same page. During inspections, focus on critical components like hydraulic systems, belts, and tires, and document any findings. By doing so, you create a reliable history of your machinery’s condition, allowing for more informed maintenance decisions and minimizing unexpected downtime in the long run. Consistency is key to keeping your equipment running smoothly.

Frequently Asked Questions

What Tools Are Best for Inspecting Construction Machinery?

When inspecting construction machinery, you’ll want to use tools like infrared thermometers, ultrasonic thickness gauges, and vibration analyzers. These will help you detect issues early, ensuring your equipment runs smoothly and efficiently.

How Often Should I Conduct Equipment Inspections?

You should conduct equipment inspections regularly, ideally monthly or after significant use. This helps catch potential issues early, ensuring your machinery operates efficiently and safely, ultimately reducing costly downtime and extending its lifespan.

Can Weather Accelerate Wear and Tear?

Yes, weather can definitely accelerate wear and tear. Extreme temperatures, moisture, and humidity can affect machinery components, leading to rust, corrosion, and mechanical failures. Regular inspections can help you mitigate these risks before they escalate.

What Are the Costs Associated With Equipment Maintenance?

Did you know that proper maintenance can reduce equipment costs by up to 30%? When considering equipment maintenance costs, factor in routine inspections, repairs, parts replacements, and potential downtime, all essential for long-term efficiency and savings.

How Can I Train My Staff on Equipment Care?

To train your staff on equipment care, start by providing hands-on workshops demonstrating proper techniques. Encourage regular inspections and create checklists. Make certain they understand the importance of maintenance for longevity and efficiency in operations.

Conclusion

Keeping an eye on your construction machinery is like having a crystal ball for your business—catching problems before they snowball into catastrophic failures. By recognizing the early signs of wear and tear, you can save yourself from costly repairs and downtime. Remember, regular maintenance and prompt attention to issues not only extend your equipment’s lifespan but also keep your projects running smoothly. Stay proactive, and your machinery will thank you by working like a well-oiled machine for years to come.